The operation of safety valves in any type of tank, whether it is a liquid gas tank, boiler or water heater, protects the tank from the risk of high pressures, and in the case of liquid gas tanks, installing a safety valve is associated with the release of gas, but if this valve is not there and the tank cracks, there is a risk. It multiplies. For basic safety measures, all tanks that are approved for liquefied gas must be equipped with a safety valve of adequate capacity. In order to be sure that the safety valve provides full protection at all times, several measures have been taken. They are as follows: They are installed on the tank, which are directly connected to the steam space of the tank and can discharge it indefinitely to the outside air. In this way, the steam is discharged, which is significantly less dangerous than the discharge of liquid. In addition, the release of steam reduces the temperature of the liquid and thus the pressure.

The safety valve must be protected and kept away from tampering, which is especially true for pressure gauges, and if the gauges are located outside, they must be sealed with an approved method.

It is obvious that between the tank and its safety valve, an additional shut-off valve should not be installed. When 2 or more safety valves are installed on the tank and the condition of the valves is such that it is possible to close one of them at any time, this operation can be done exceptionally. The valve or other valves must have the necessary capacity to protect the tank. Using a multi-way safety valve makes it easy to pull out, test, and perhaps replace the safety valve because it eliminates the need to empty the tank. Testing the safety valve is usually not necessary, but it has been observed that in the case of tanks with a capacity of more than 2000 gallons, it is better to perform such tests at intervals of 5 years.

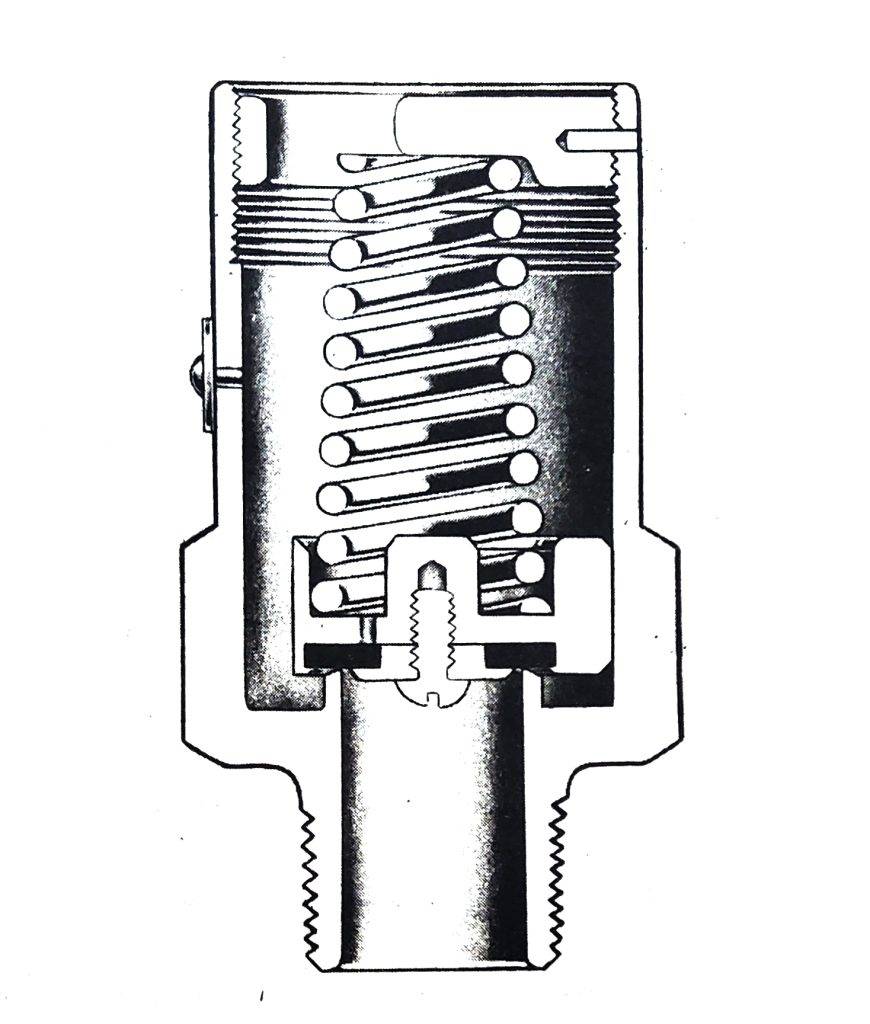

Figure 5. A section of a spring safety valve whose different parts are:

Page, the amount of sealing, the spring part and the valve, what is not shown is a “drain” hole at the bottom of the upper part from which the liquid vapor escapes.

Capacity of the safety valve

Safety valve capacities may be indicated in two ways on the rating plate attached to the valve. Older taps were marked with a number, for example, 3046, without using any other symbol. This number represented the capacity of the safety valve in cubic feet per minute of liquefied gas. Since 1952, the specification pages have the word “air”, which means that it is clearly shown that the capacity is in cubic feet per minute of air.

This issue simplifies the determination of the size of the safety valve because the required capacities are also expressed in this way.

Causes of safety valve opening

1. An obvious reason for the opening of the safety valve is the presence of a fire near the fuel tank. In such cases, it is better to burn the volatile gas before it accumulates in sufficient quantity and causes an explosion.

2. In some areas, the high temperature in summer causes the safety valve to open. At temperatures greater than 100 degrees Fahrenheit, the pressure of the relief valve assembly may increase from 220 to 250 pounds. In order to prevent such discharge, a material with a lower vapor pressure may be used. With colors that reflect the heat or creating shade for the tanks or cooling them with the help of water splashing.

3. Since overfilling the tank is accompanied by a sufficient increase in temperature, it will certainly lead to the opening of the safety valve, and as soon as the liquid expands and completely fills the tank, the hydrostatic pressure of the tank increases and a further increase in temperature causes a further increase in pressure and As a result, the opening of the valve is ensured.

4. If “hot” material or unsuitable material is poured into the tank, it may cause the pressure to rise and the safety valve to open. As mentioned earlier, the fuel supplier must be sure that the tank is suitable for his product.

5. Sometimes quickly filling the tank causes the safety valve to open. When the liquid enters the tank, the vapor inside the tank is compressed and takes up less space. If the vapor pressure is higher than the vapor pressure of the substance, the vapor turns into liquid and reduces the pressure. However, if the pressure build-up is faster than the steam condensate, it may reach the limit of the safety valve opening pressure. In order to minimize the possibility of creating this pressure, for tanks with a capacity of between 30 and 2000 gallons of water, it is a definite rule to fill the vapor space. Using a pressure equalizing line is an effective way to prevent excess pressure when filling the tank.

6. Inaccuracy in cleaning the tank for the first time may cause an abnormal rise in pressure. The pressure of the compressed air in the tank combined with the normal vapor pressure of the material, even at moderate fuel temperatures, will certainly cause the safety valve to open.

In all cases, the discharge of the relief valve must be such as to protect it from physical damage.

Safety valve discharge criteria

DOT (ICC) ASME (120 gallons or less): Relief valves must be installed to minimize the possibility of discharge to the tank.

ASME (125 gallons or more) and portable tanks (125 gallons or more) gas trucks: Discharge should be upward away from the tank and released into the open air. Safety valve vents should be protected from natural hazards and if protective caps are used, they should not be removed except when draining.

Above ground (over 2,000 gallons): Relief valve discharge must be vertical and at least 7 feet above the open air tank. If necessary, drain pipes with certain criteria should be installed for waste materials. The inlets and outlets of waste materials should be designed in such a way that the possibility of the flame approaching the tank is eliminated. The piping of the tank and other adjacent parts must be protected from the risk of fire.

Underground (greater than 2,000 gallons): Relief valve discharge must be directly upward at a point at least 7 feet above the ground. Draining for tanks installed in liquid gas service stations should be done directly upwards and at a point at least 10 feet above the ground.

Determining the size of safety valves

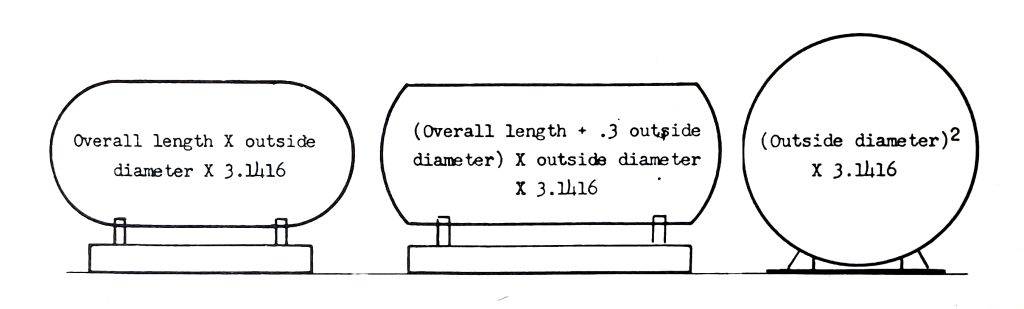

It is not always necessary to determine the size of the safety valve for a liquid gas tank, but it is necessary in cases where the safety valve must be replaced or the main signs are not legible. Since the amount of heat entering the tank is more or less proportional to the external surface, the capacity of safety valves is determined based on this principle. It should be noted that underground tanks are relatively safe against fire and the heat of the sun. For this reason, the necessary amount of capacity of the safety valve is reduced. The required capacity is as follows:

If the tank is installed underground, the capacity of the safety valve may be up to 30% of the specified amount of liquid, and liquid gas cannot be poured into it until it is completely covered by soil, and after the source is completely emptied, the soil must be filled. removed from it.

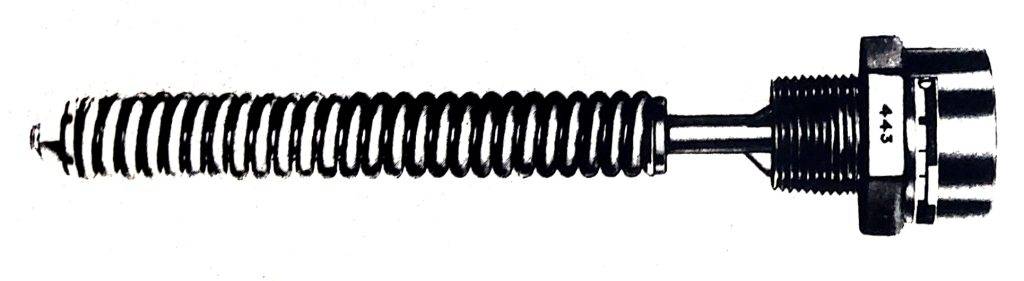

Figure 6. The internal part of the valve ensures that its moving parts are protected from external damage. This type of protection is required for vehicle fuel tanks.

If there is a deviation from the above criteria, or if a part of the tank is underground, such a tank should be considered an above-ground tank when determining the capacity of the safety valve.

Of course, there are other possibilities and everyone can refer to the manufacturer’s brochure before choosing.

Valve preventing excess flow

A valve to prevent excess flow is a valve that allows steam or liquid to flow in any direction, but if the flow in one direction exceeds the specified limit, the valve is closed and it is possible to prevent the excess flow of fluid into the tank by means of the valve. . The flow to the outside will not be interrupted until the flow rate exceeds the capacity of the valve.

Whenever there is a leak or a burst in the pipelines, the added flow will close the valve and thus prevent the release of fuel in a dangerous volume. A small by-pass about the size of a #60 hole is connected to the overflow stop valve to balance the pressure. When the valve starts working, the pressure inside the tank keeps it closed. The fluid flow is cut off from the valve itself, except for a small amount that passes through the bypass. When the repairs are done and the flow of material to the atmosphere is stopped, due to the existence of the bypass, the pressure in the direction of the flow of the valve starts to rise. When the pressures are balanced, the internal spring opens the valve and causes the fluid to flow. Valves preventing excess flow

It is necessary to protect the tank entries, but the following exceptions are allowed:

Filling connection: This connection is exempted because the approved filling valves have the necessary safety devices.

Safety valve: No type of valve can limit the flow of the safety valve. Because this leads to disruption of the normal flow of the safety valve. Of course, this article is not correct about orifice safety valves.

Measuring devices: If the inlet from which the gas can escape is smaller than hole number 54 and these inlets are related to liquid level measuring devices or pressure measuring devices, there is no need for a valve to prevent excess flow.

Intake outlet pipe: For ASME tank system, no additional flow stop valve is required for intake lines if the following conditions are met.

(a) The water capacity of the tank is not more than 2000 gallons of water (W.C).

(b) The outlet of the service line is equipped with a manual shut-off valve equipped with a valve or equivalent. (The method of connecting this shut-off valve is subject to certain restrictions.)

(c) The diameter of the controlling orifice between the tank and the outlet of the shut-off valve should not be larger than inches for steam exit and inches for liquid exit.

(d) an approved pressure reducing regulator connected directly to the outlet of the shut-off valve, or having a solid support or strong enough to provide adequate protection on the tank or inside it, and by means of an interface capable of A suitable spring is connected to the shut-off valve.

An internal quick-close valve: This valve is designed to remain closed at all times except during operation and may be used in place of an overflow stop valve. When these valves are installed on portable ASME tanks or gas trucks, they must follow certain criteria.

Capacities of valves to prevent excess flow

The location of a valve is to prevent excess current, like a fuse in an electrical system. If the current is more than the fuse capacity, the fuse cuts the circuit. The amount of fuse capacity depends on the line used. The same goes for the overflow check valve. It is necessary to close the valve automatically when the amount of steam or liquid flow exceeds the specified limit. In other words, if the capacity of the valve is 100 gallons per minute, the valve should be closed whenever the flow rate exceeds this amount.