Cryogenic tanks

Cryogenic Tanks

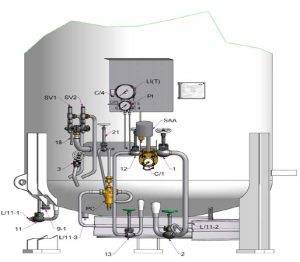

Fixed cryogenic tanks are engineered for the long-term storage of cryogenic liquefied gases under pressure. The inner tank is constructed from austenitic stainless steel, while the outer tank is made from carbon steel. These tanks can be oriented vertically or horizontally and are suitable for storing LIN (liquid nitrogen), LOX (liquid oxygen), LAR (liquid argon), LNG (liquid natural gas), CO2, and N2O.

Moreover, these tanks feature dual-wall construction with vacuum insulation, utilizing perlite between the walls to ensure optimal thermal performance. Additionally, the maximum allowable pressure for fixed cryogenic tanks varies from 2 bar to 37 bar, depending on the specific application. The design temperature range spans from -196°C to 50°C, thus accommodating the diverse requirements of cryogenic storage.

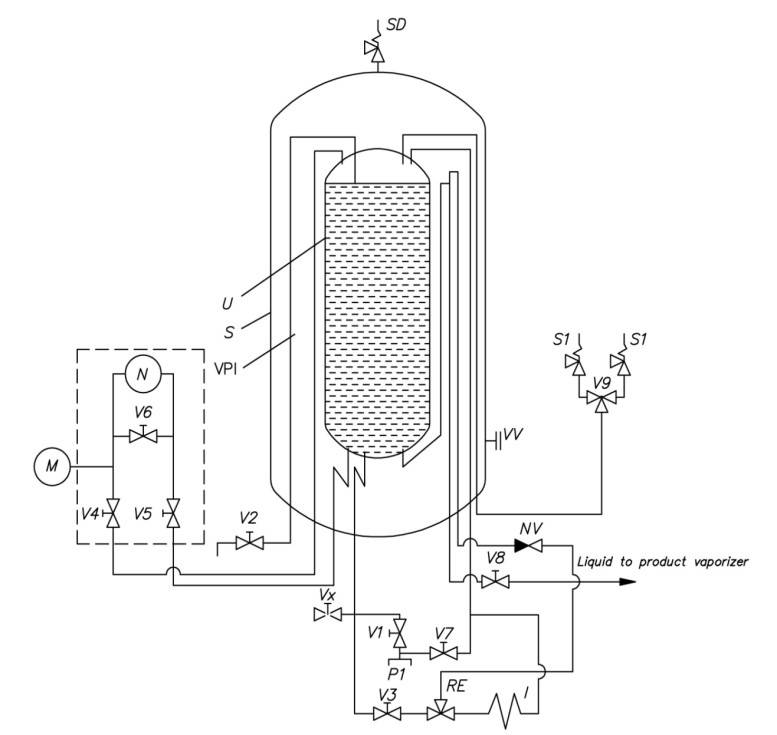

V1 liquid loading/discharging valve from the bottom

V2 overflow valve

V3 pressure increase valve

V4 pressure gauge valve/percentage gauge (top)

V5 percentage meter (bottom)

V6 balance valve (bypass)

V7 liquid filling valve from the top / gas exit from the top

V8 liquid that goes to the evaporator

V9 three-way valve / diverter valve

VV vacuum valve

I auxiliary evaporator

VX liquid output (optional)

M manometer

N percentage gauge

RE regulator

P1 download interface

NV check valve

-

Components of cryogenic transport tanks:

- General symptoms of the system:

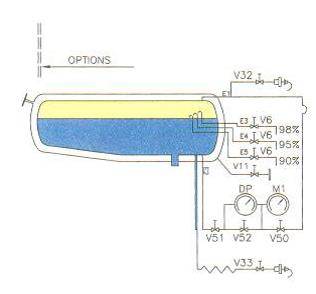

- M1: The pressure gauge that shows the tank pressure should be below the red mark that indicates the MAWP. To prevent the pressure from increasing, the tank should be emptied or the safety valves should be opened.

- DP: (Difference Pressure gage) shows the volume percentage of the tank. Using the conversion table, it is possible to obtain the equivalent volume in terms of liters or cubic meters for each gas.

- V50 and V51: They should be open for easy reading.

- V52: It is used for DP control.

- V6 faucets (Trycooks): To show the liquid level.

- The liquid level in the tank should not be filled more than 95%.

- V32 valves: For gas sampling

- Lion V33: Lion V33:

- V32 and V33 valves must be equipped with Quick Coupling at their ends.

- V11: Vacuum control valve. It should be used only by authorized personnel.