Ammonia tanks

- Ammonia is used in the preparation of nitrogen fertilizers, acrylonitrile, nitroparaffin and nitrocellulose synthetic fibers, ammonium sulfate, ammonium nitrate.

- Ammonium phosphate and urea, production of pharmaceuticals, ice factories, household appliances and refrigeration industries, production of nitric acid

- In the chemical and petroleum industries, production of nitrogenous compounds, in gas transmission technology, drilling and extraction of various metals, explosives, leather making, metal baking operations, rubber and fiber industries (preventing premature aging of rubber),

- It is used in paper and wood pulp industries, metallurgical industries (extraction of metals such as copper, zinc and nickel) and food preservation.

Ammonia is one of the most widely used mineral chemicals, whose global production was reported to be 175 million tons in 2018.

Anhydrous ammonia is classified by the DOT as a non-flammable gas, Group 2.2 and an inhalation hazard.

Compressed air should not be used to transport ammonia from containers and cargo tanks because it causes ammonia pollution.

Ammonia is flammable in air in the range of 16 to 25% by volume, but mixing oil with ammonia extends this range. Therefore, ensuring the absence of flame sources or sparks in storage or use areas of ammonia is essential.

Ammonia tanks are made in fixed and transportable form. Transport tanks are categorized into ISO container, cargo tank, and portable tanks.

Weera Khazar tank company has the ability to manufacture these tanks from 500 liters to 200,000 liters.

The equipment of these tanks must have the ability to be compatible with ammonia, and if requested by the employer, it is possible to supply equipment from famous brands such as REGO or DANFOSS.

Construction standards for ammonia tanks:

ASME SEC8 DIV1 , ADMERKBLATT, EN14025, ADR, DOT, BS5500

Tips for building ammonia tanks:

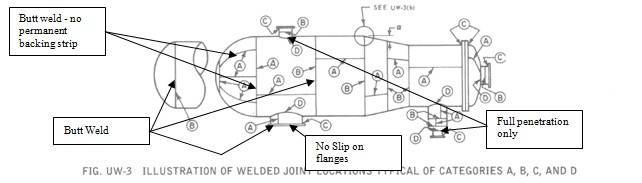

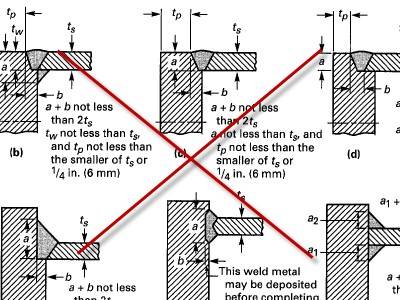

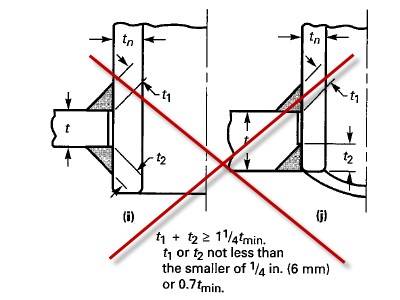

- The type and classification of the welding seam used

- It is forbidden to use the following connections for welding:

- The connection of the nozzle to the body must have full penetration:

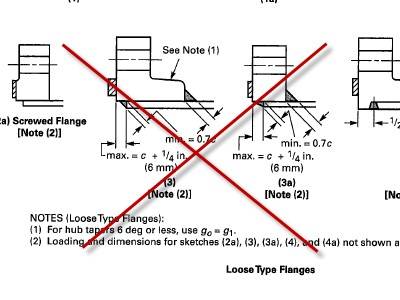

- It is forbidden to use the following flanges: